Die Design &

Manufacturing Features

Cimatron Die Design Features

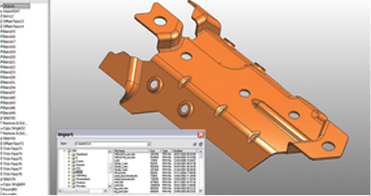

Data Import

Import customer data and start working immediately

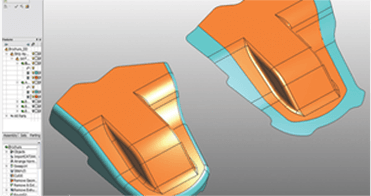

Blank design & forming

Work on forming shapes easily, quickly, and efficiently

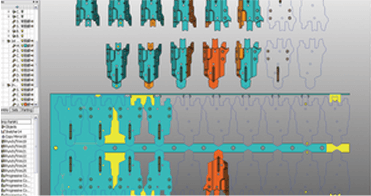

Die layout

A dedicated strip design environment to tincrease productivity

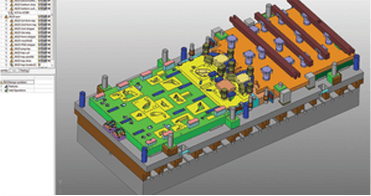

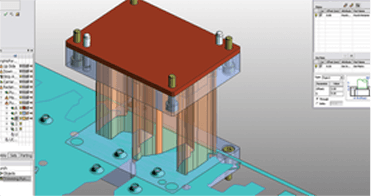

Die set design

Load an entire die set fully adapted to your current requirements within seconds

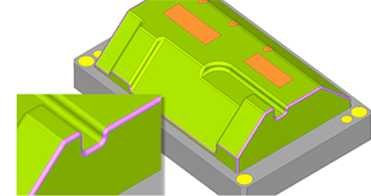

Punch/matrix design

Select from a variety of applicative tools and powerful modelling capabilities to simplify and accelerate punch creation

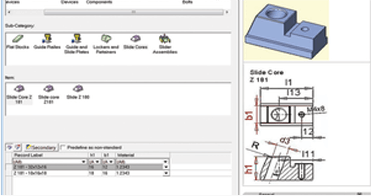

Catalog Parts

Work with a diverse variety of commercial catalogst

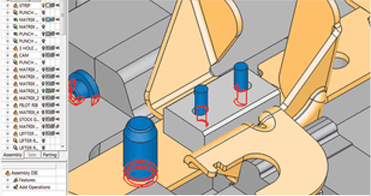

Collision detection & motion analysis

Leverage the 3D design environment to visualize the design in different stages of development and erase errors

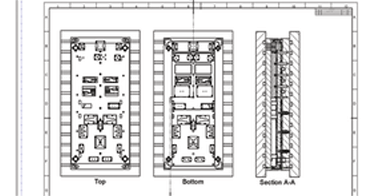

Drawing

Build on drawing templates that incorporate customer specifications

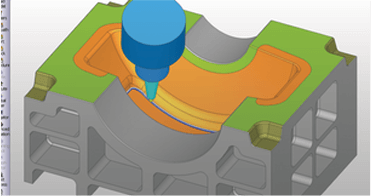

Built-in CAD functionality

Achieve the best machining results powered by built-in CAD functions

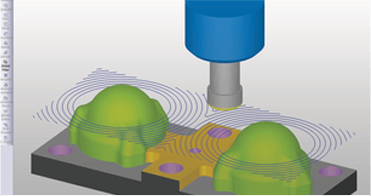

Efficient Roughing

Maximize material removal rate and prolong tool life

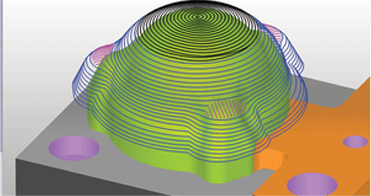

High-quality finishing

Select from a set of 3 to 5 axis-optimized machining strategies to achieve a high quality surface finish

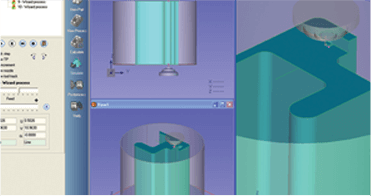

Full 5-axis capabilities for mold making

Reduce set-up time, shorten machining time, and improve surface quality

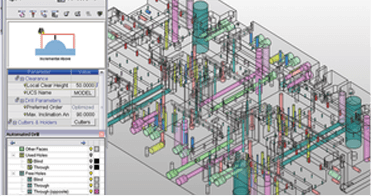

Plate machining and drilling

Powerful capabilities and toolpaths to ensure efficient and accurate machining of plates

Simulation and post

processor support- Engage in machining with confidence and predict results on the basis of simulation and post-processor support

NC set-up and tool table reports

Facilitate symmetry of information between NC programmers and the shop floor

Wire EDM programming

Program you wire EDM machines quickly and easily with ample room for custom settings